P-51D "Roto-Finish" Build Log-Custom Plastic Pieces

The P-51D Mustang makes use of an interesting feature to help maintain engine cooling and efficient airflow. North American engineers designed the radiator tunnel to create thrust taking into account the temperature differential and the Meredith effect. It's a characteristic of cool (ambient) air entering the scoop, decreasing in velocity due to the widening of the tunnel, drawing heat out of the radiator coolant and increasing in velocity as it exists the tunnel outlet. This action actually produces thrust for the aircraft. The thrust gained is less than the weight of the scoop and tunnel. His example references a 200 pound thrust force....but the race modified scoop can weigh up to 600 pounds in it's entirety. Even though the thrust accomplished by this design does not fully overcome the 600 pounds of race scoop, it diminishes it's presence by 200 pounds at cruise, at altitude.

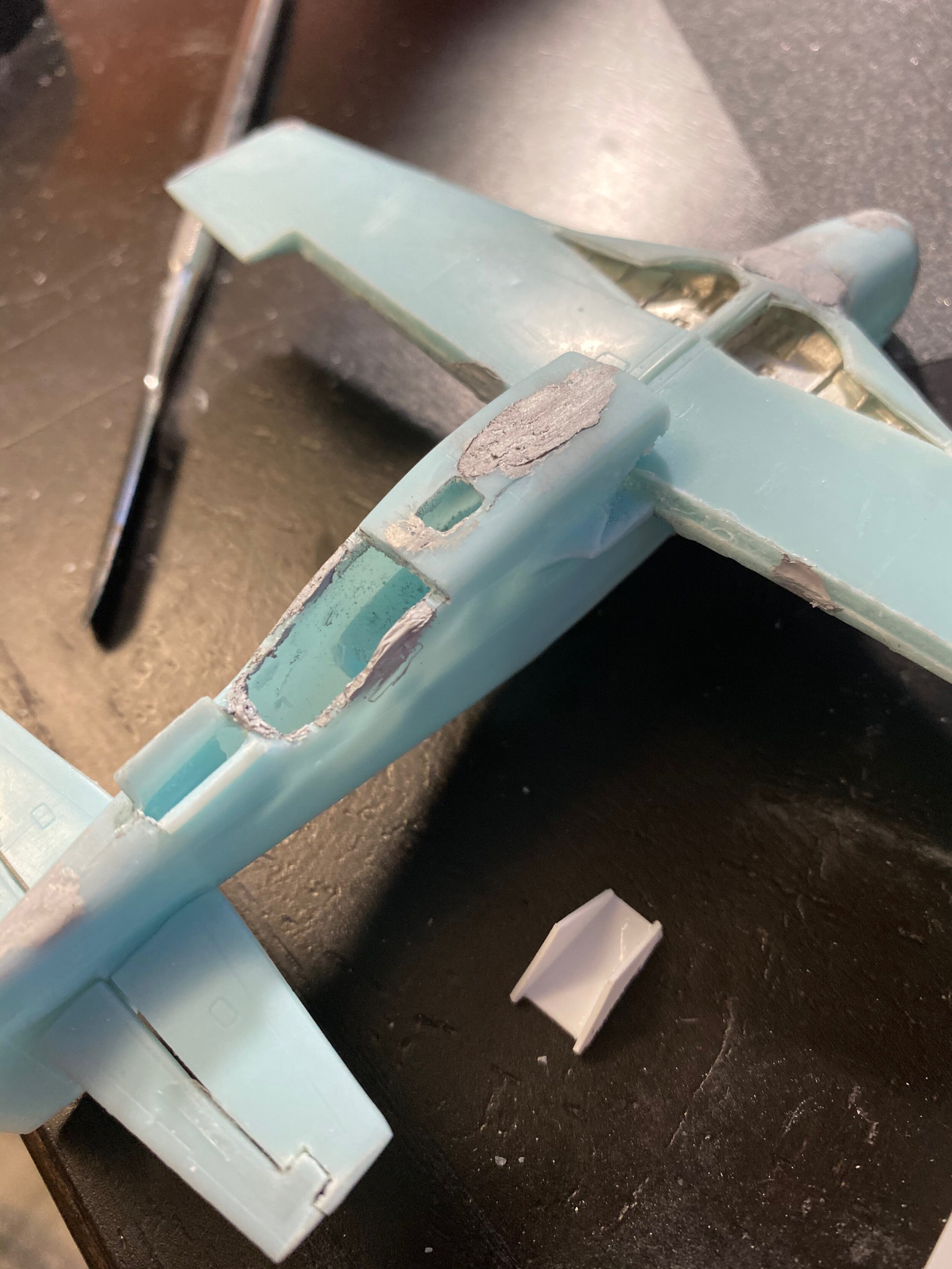

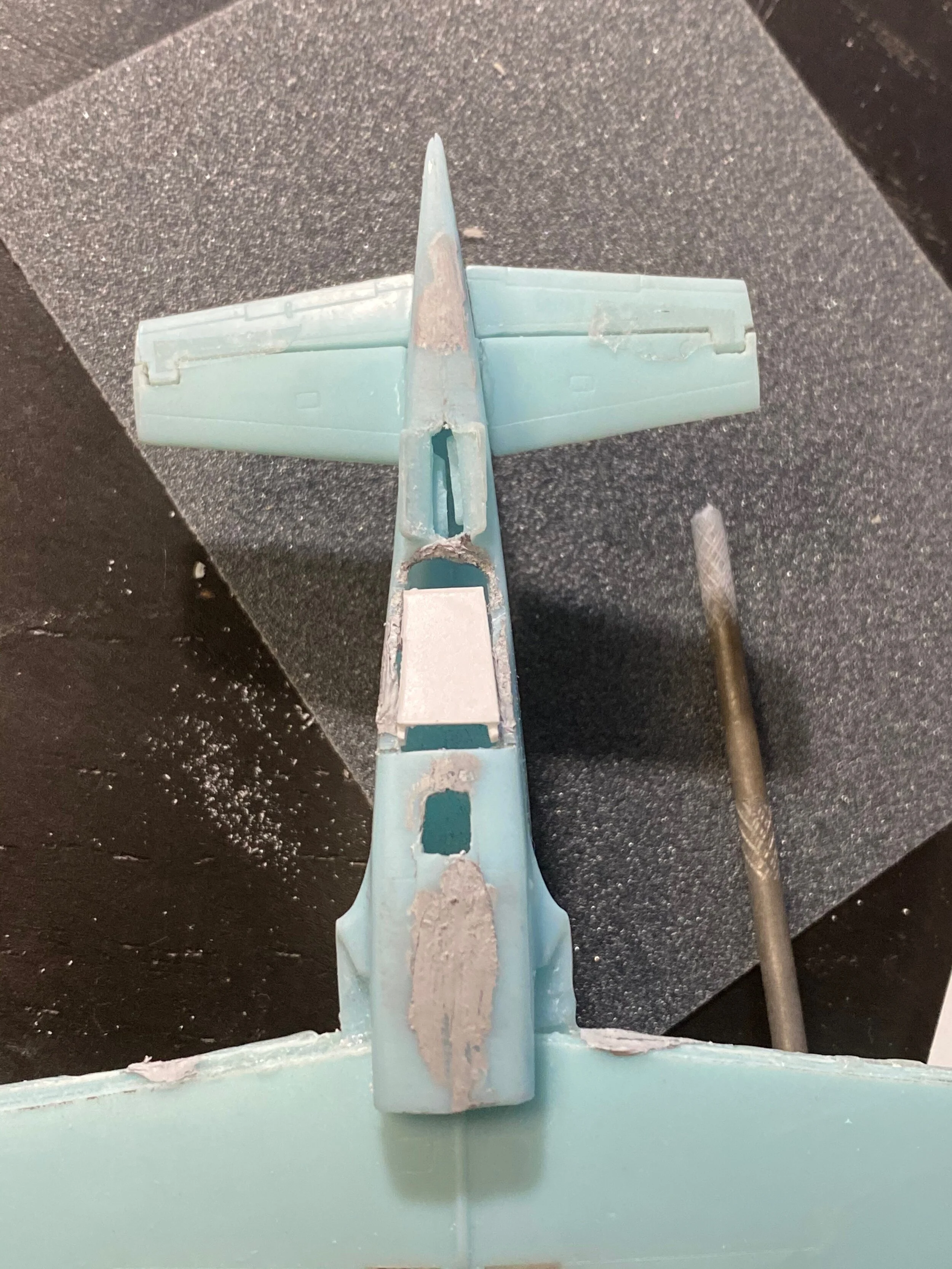

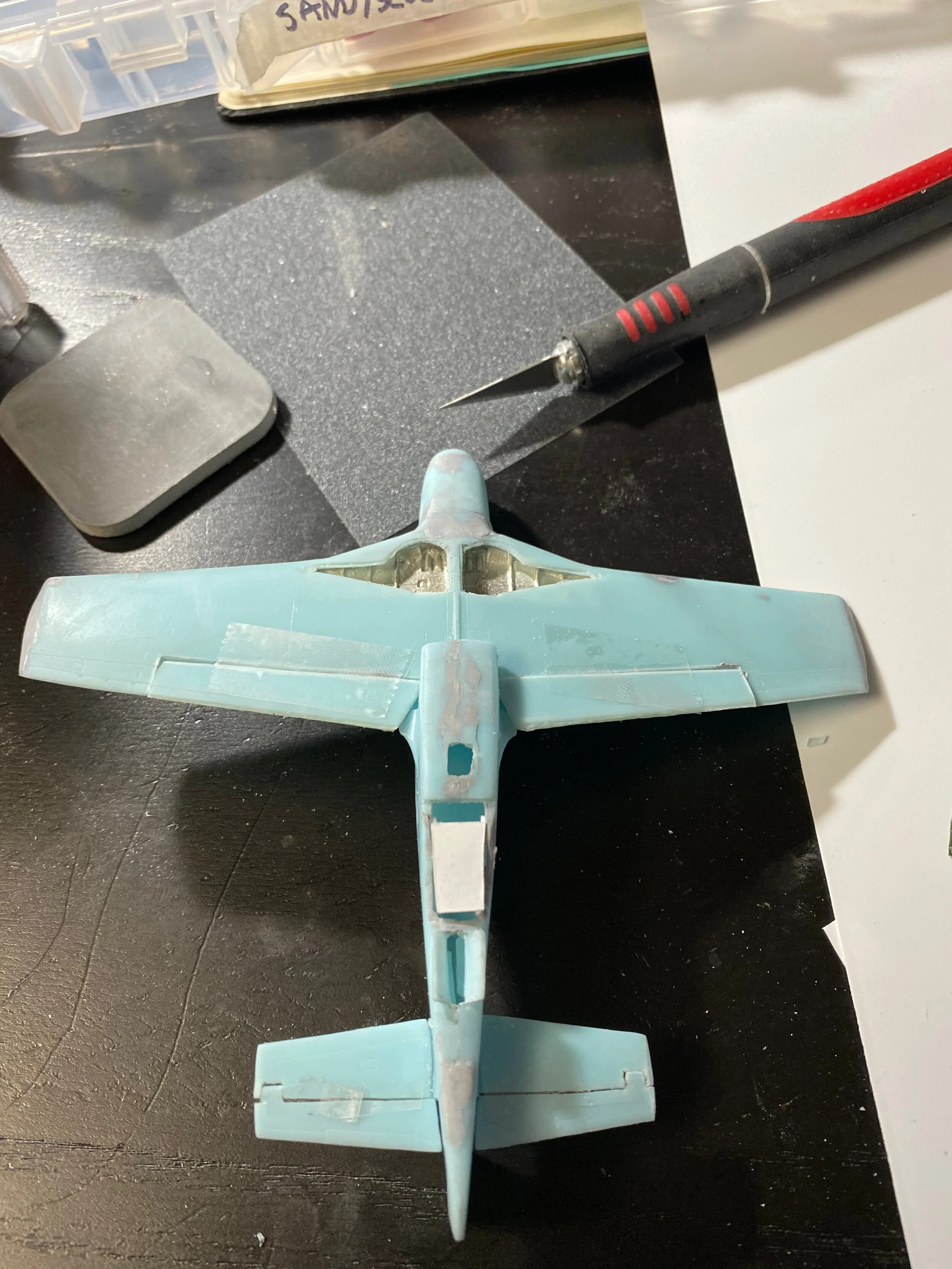

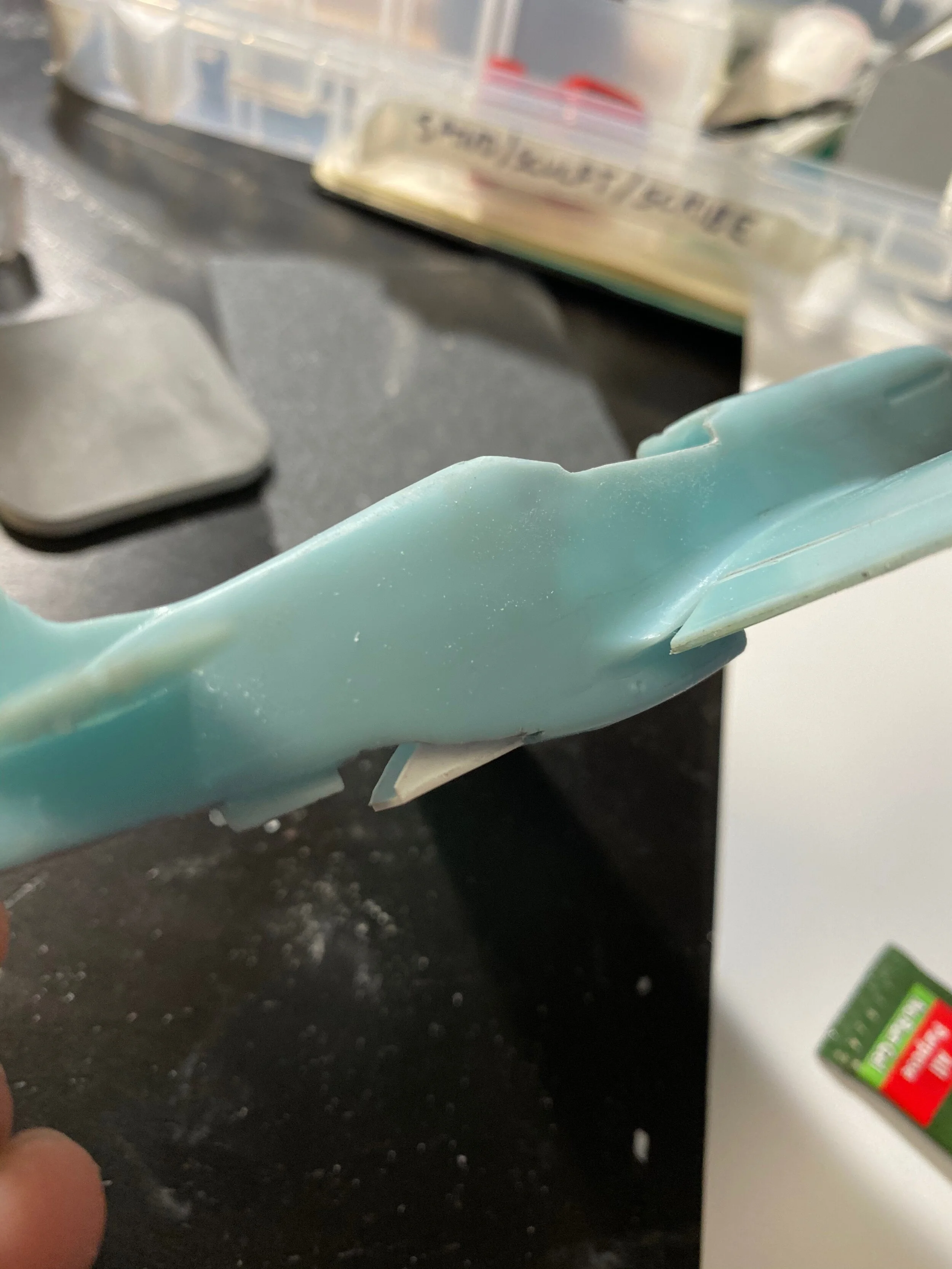

I typically like to show the radiator doors open and with this scale I decided to custom build it using Evergreen sheet plastic stock (.020” Thick). I first had to clear-out the moulded plastic slot to make room for the custom scoop.

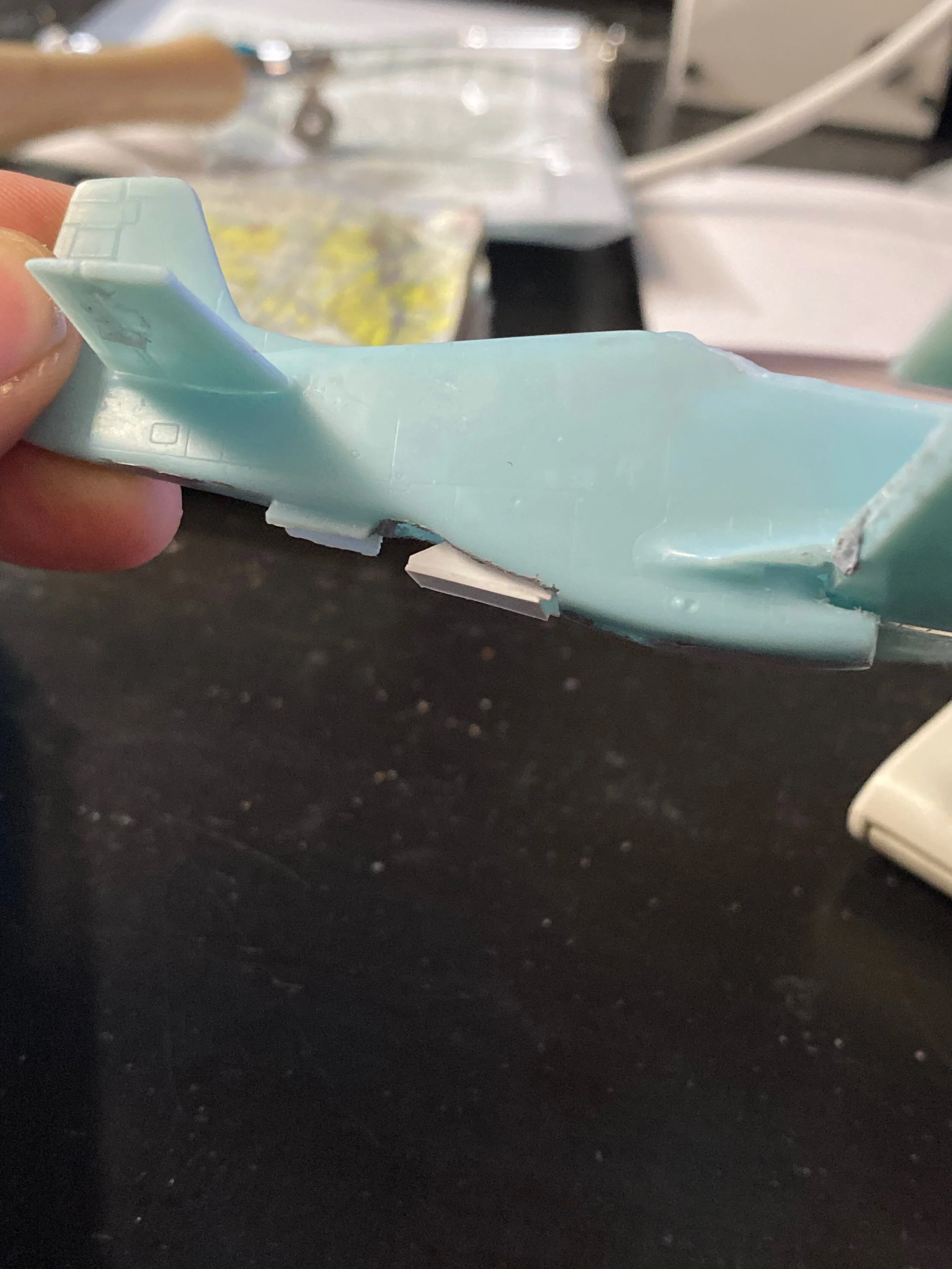

The radiator door I created with 3 pieces cut-out of the polystyrene sheet. The cuts on plastic this thin can be done with the X-Acto blade without the cutting saw. The pieces were glued together with super-glue gel and zapped with Insta-Set spray. This allowed the glue to fill in any marginal gaps in the door.

The door fitting was tested and additional sanding was completed to square out the assembly. Extra modeling putty was used to build back up the rounded section that moulds around the scoop. You can see the scoop in-place in the photos below before final fitting.

Next-up, we’ll work on the propeller and get as much scale as possible by separating the blades from the spinner and cleaning up the overall assembly.

P-51 Radiator Scoop (below wing) and Adjustable Coolant Air Scoop)